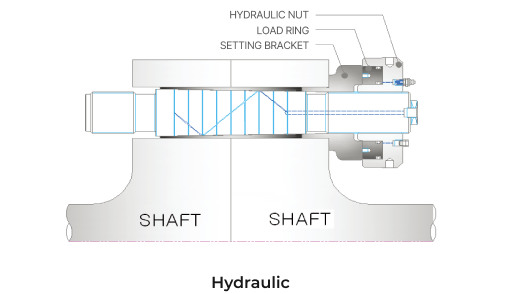

Hydraulic

Bolt / Nut

Bolt / Nut

Hydraulic Coupling Bolt product uses excellent materials that have gone through a forging process

and has high strength and resistance to shock or vibration.

Its expansion of the inclined sleeve strengthened the fastening force, and it shows strength in safety

and handiness through hydraulic installation and disassembly and no damage to the flange

during disassembly compared to Reamber Bolt.

and has high strength and resistance to shock or vibration.

Its expansion of the inclined sleeve strengthened the fastening force, and it shows strength in safety

and handiness through hydraulic installation and disassembly and no damage to the flange

during disassembly compared to Reamber Bolt.

Hydraulic

Coupling Bolt

Coupling Bolt

| 10 Set Standard |

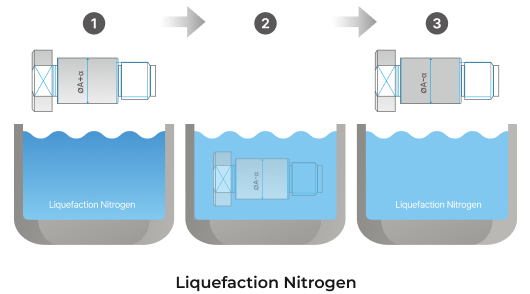

Hydraulic Coupling Bolt (New Type)

|

Reamer Bolt (Old Type) |

|---|---|---|

| Install | Hydraulic | Liquefaction Nitrogen |

| Dismantle | Hydraulic Oil Injection Adaptor & Disjoint Sleeve Semi-Permanent | Shaft Flange Heat (Bolt Damage Frequenct High) |

| Install Time | 0.5Hour ~ 1Hour + α | 6Hour ~ 8Hour + α |

| Dismantle Time | 0.5Hour ~ 1Hour + α | 3 Days + α |

| Remark |

|

|

|

|

Hydraulic

Coupling Bolt

Coupling Bolt

Capability

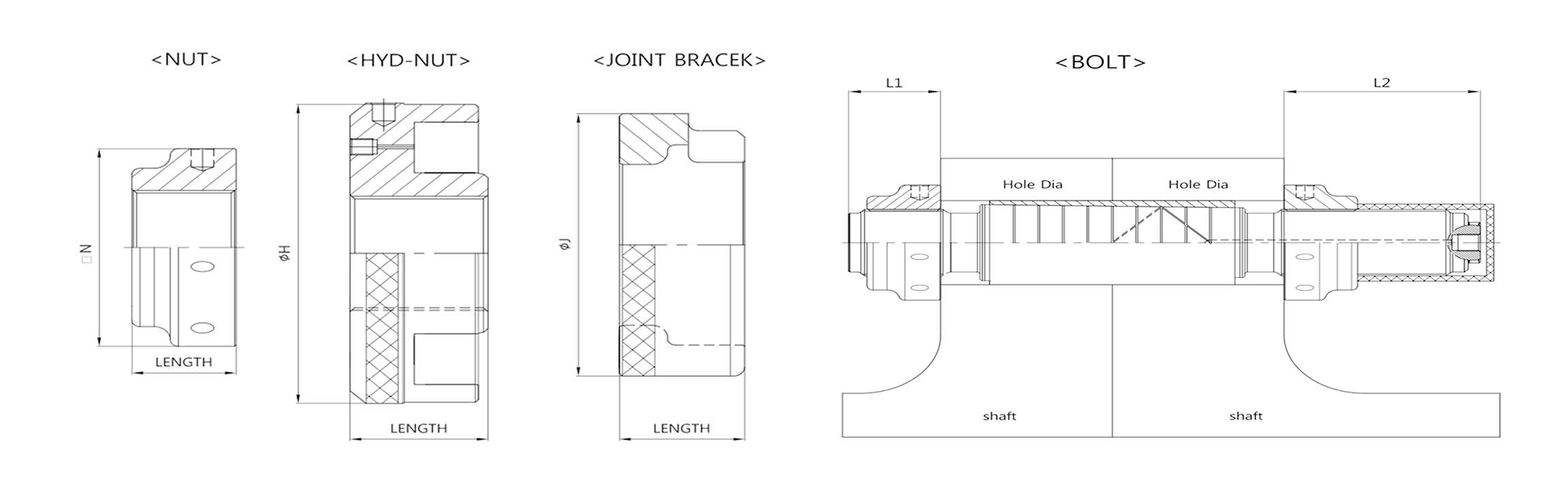

| M | D | BOLT | NUT | HYD-NUT | JOINT BRACKET | ||||

|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | øN | LENGTH | øH | LENGTH | øJ | LENGTH | ||

| 32 | 41~45 | 42 | 66 | 60 | 270 | 95 | 41.4 | 83 | 34 |

| 36 | 46~50 | 47 | 70 | 60 | 30 | 95 | 41.4 | 83 | 34 |

| 40 | 51~55 | 55 | 105 | 80 | 40 | 145 | 55.5 | 133 | 51 |

| 45 | 56~60 | 55 | 105 | 80 | 40 | 145 | 55.5 | 133 | 51 |

| 50 | 61~65 | 60 | 110 | 88 | 45 | 150 | 56.5 | 138 | 58 |

| 55 | 66~70 | 72 | 125 | 104 | 52 | 163 | 61 | 146 | 59 |

| 58 | 71~75 | 72 | 125 | 104 | 52 | 163 | 61 | 146 | 59 |

| 60 | 76~80 | 72 | 140 | 114 | 55 | 180 | 73 | 158 | 66.5 |

| 65 | 76~80 | 75 | 140 | 114 | 55 | 180 | 73 | 158 | 66.5 |

| 70 | 86~90 | 75 | 147 | 127 | 58 | 195 | 73 | 173 | 70 |

| 75 | 91~95 | 78 | 160 | 130 | 60 | 200 | 76 | 175 | 73 |

| 80(78) | 96~105 | 85 | 165 | 141 | 60 | 214 | 78.5 | 193 | 77 |

| 85 | 106~110 | 85 | 172 | 156 | 65 | 237 | 86 | 207 | 78 |

| 90 | 111~115 | 85 | 172 | 156 | 65 | 237 | 86 | 207 | 78 |

| 95 | 116~120 | 95 | 178 | 156 | 69 | 237 | 86 | 207 | 82 |

| 100 | 121~125 | 95 | 178 | 156 | 69 | 237 | 86 | 207 | 82 |

| 105 | 126~130 | 97 | 187 | 177 | 84 | 274 | 90 | 247 | 99 |

| 110 | 131~135 | 97 | 193 | 179 | 84 | 294 | 90 | 258 | 99 |

| 115 | 131~140 | 97 | 193 | 179 | 84 | 294 | 90 | 258 | 99 |

|

|||||||||

*This is data based on a standard-sized material, and it can be manufactured according to customer requirements.

(Special designs are available to suit customers requirements)

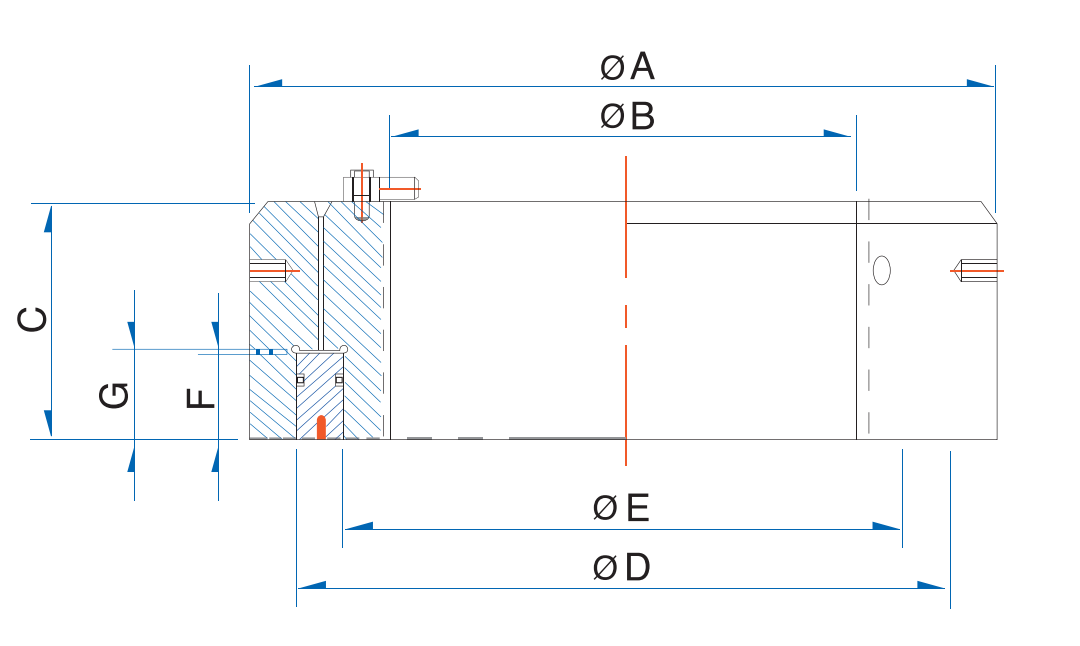

Hydraulic Nut

Capability

| Model No | Dimension | Pressure(kg/cm²) | Size(M) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| øA | øB | C | øD | øE | F | G | |||

| SBN 250 | 520 | by request | 180 | 440 | 360 | 65 | 70 | MAX 1500 | M250 |

| SBN 300 | 580 | by request | 250 | 495 | 410 | 70 | 75 | MAX 1500 | M300 |

| SBN 350 | 635 | by request | 225 | 545 | 455 | 75 | 80 | MAX 1500 | M350 |

| SBN 400 | 690 | by request | 240 | 595 | 500 | 85 | 90 | MAX 1500 | M400 |

| SBN 450 | 745 | by request | 255 | 645 | 545 | 90 | 95 | MAX 1500 | M450 |

| SBN 500 | 805 | by request | 270 | 700 | 595 | 95 | 100 | MAX 1500 | M500 |

| SBN 550 | 860 | by request | 285 | 750 | 640 | 100 | 105 | MAX 1500 | M550 |

| SBN 600 | 920 | by request | 300 | 805 | 690 | 105 | 110 | MAX 1500 | M600 |

| SBN 650 | 975 | by request | 310 | 855 | 735 | 110 | 115 | MAX 1500 | M650 |

| SBN 700 | 1035 | by request | 325 | 910 | 785 | 120 | 125 | MAX 1500 | M700 |

| SBN 750 | 1090 | by request | 340 | 960 | 830 | 125 | 130 | MAX 1500 | M750 |

| SBN 800 | 1200 | by request | 370 | 1060 | 920 | 140 | 145 | MAX 1500 | M800 |

*This is data based on a standard-sized material, and it can be manufactured according to customer requirements.

(Special designs are available to suit customers requirements)